DLT 4.0+ energy efficiency wide-body roller kiln for sintered slab tile production once again sparked the enthusiasm of insiders in the industry of ceramics. In a couple of hours, the formation process of real stone which takes thousands of years in the natural environment is reproduced in an industrial sintering process. Pieces of jade like, crystal clear beautiful sintered slab tiles appear leisurely and brilliantly on the production lines.

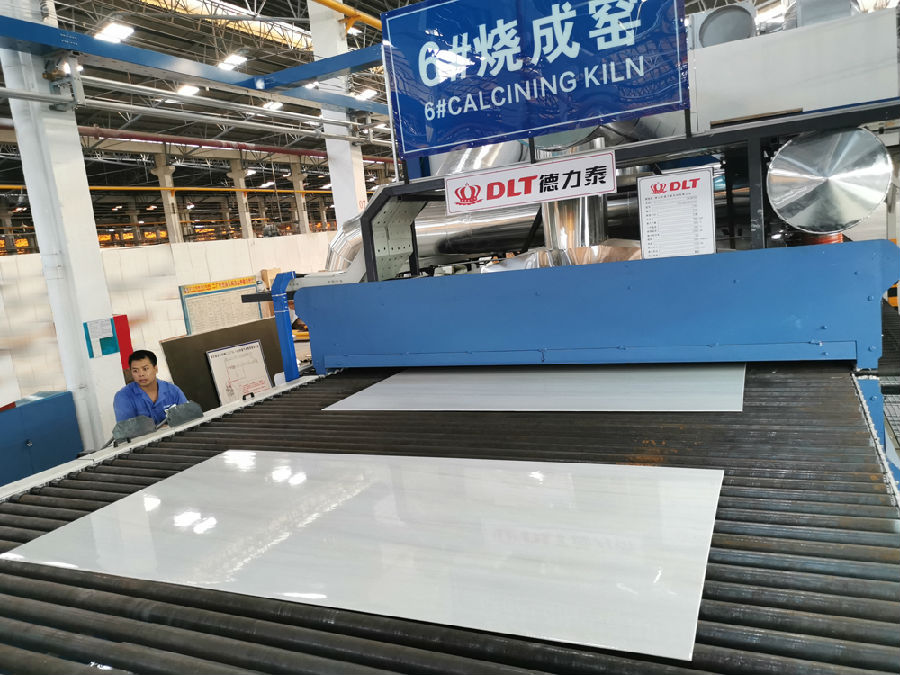

On June 18th, 2020, a DLT high-end Industry 4.0+ energy efficiency wide-body roller kiln for sintered slab tile launched trial production at New Pearl Green Building Materials R&D & Production Base in Zhaoqing City, Guangdong Province.

The smooth running of the high-end sintered slab tile production line not only shows New Pearl Group’s great development and strong competitiveness in the field of sintered slab tile, but also starts a new journey for New Pearl to march along the road of green and smart manufacture.

As early as 2017, New Pearl started its first green manufacture sintered slab tile production line in its initial deploy program aiming at the market of sintered slab tile.

For decades of years, New Pearl Group has kept continuously exploring in product innovation, technology improvement and equipment upgrading, and has put great efforts in promoting the popularization, guiding the consumption and widening the use range of sintered slab tiles.

Summit, as New Pearl’s pioneer brand in the group’s globalization plan, is focusing on product concept innovation in the field of sintered slab tile. It is devoted to the comprehensive application solutions of sintered slab tile for home decoration by creative indoor design and aesthetic space utilization.

In order to develop high quality sintered slab tiles, Summit has introduced a DLT 4.0+ energy efficiency YEB series wide-body roller kiln, a DLT high efficiency five-layer dryer with auxiliary equipment, in addition to an Italian SYSTEM 20000-ton press and other top branded equipment in the industry.

To meet the current market demand, with more than 20 years’ accumulated experience in the international market, and based on the success of more than 10 sintered slab tile kilns in India, combined with years of technical achievements on sintered slab tile kilns from Welko, a Keda subsidiary in Italy, DLT team has successfully developed the new generation of YEB series kilns with 4.0 + energy efficiency technology.

The main product sizes produced by Summit include 1200×2400mm, 1200×2700mm with 6-9mm thickness and 600×1200mm with 10mm thickness, while various sizes are available via flexible customized production.

The kiln features scientific modularized configuration and elegant appearance, not only with optimized design in fast firing, preheating and other aspects such as cutting loss elimination, but also with scientific and specific improvements in energy saving, tile smooth running, temperature difference control, automatic and intelligent production, etc.

In particular, the performance on the first day of production shows that DLT has solved the technical problem of tile cutting crack. By using recycled hot air for premixing the cooling air and a step-by-step cooling down process, the internal stress of tile can be fully discharged, and as a result, tile cutting can be done through the whole cutting length without any sudden crack in the half way.

Moreover, in addition to IFGR regenerative burners, KHI updated insulation system and DMA movement control system, the kiln is also equipped with DHR heat recovery system (Patent Number: ZL2016010992314.3) , an exclusive technology developed by DLT, able to reduce unit natural gas consumption and improve the environment quality as well.

What’s more, the kiln has achieved a zero discharge of waste air from the final cooling zone of kiln. Without starting any of the standby hot air generators, only the recycled hot air from the kiln can sufficiently meet the heat demand of the 5-layer dryer, the combustion air for the kiln burners and the heating source for the glaze line dryer.

The multi-layer self-circulation dryer which is with a full cover structure design has advantages of good air-tightness, high drying efficiency, zero tile breakage and space saving. It not only has stable performance and good adaptability to the low-strength formula of tile body, but also can provide high quality green tiles for fast firing at lower temperature. The efficiency of heat recovery and benefits hence obtained are unbeatable in the market.

Equipped with the patented technology, PPC super energy saving system, and OCE optimal combustion eco system, the kiln can effectively reduce fuel consumption under normal production condition.

In particular, the pipe type kiln fume heat exchanger can absorb heat from exhaust fume of kiln to produce clean hot air at high temperature, which can be used for warming up the kiln combustion air and the dryer heating source, and can consequently reduce the consumption of gas. As jointly used with DHR system, the temperature of combustion air can be increased up to 200 celsius degree, thus further reducing the gas consumption.

Armed with the powerful technology in energy saving, DLT has greatly supported New Pearl Group to carry out its large sized sintered slab tile program and lead the market to a new stage.

Each piece of sintered slab tile produced by Summit is not only professionally created, but also exquisitely culture-loaded. The combination of fire and clay is an art endowed with unique aesthetics of building ceramics. It meets the consumption demands of different levels of population in an all-round way, guiding the home decoration trend, showing the boundless imagination and potentiality of artisans, and creating the real beauty of daily life.

By joining hands with leading brand-builders in the industry, DLT has successfully achieved the updating in Industry 4.0+ sintered slab tile production technology with brand-oriented quality control and green manufacture concept. Backed up with new technologies, new materials and new applications, DLT will keep continuous innovation in the drying and firing technology, and with its advanced production techniques, up-to-date energy-saving design and timely technical support, DLT will surely make more and greater contribution to the ceramic industry in the coming future.

简体中文

简体中文 English

English

News Center

News Center